MEN G Fei , GUO Shi2ju , ZHAN G Heng , YAN G Xia , GUO Lin (Powder Metallurgy Institute , University of Science and Technology Beijing , Beijing 100083 China) Abstract : Effect of various metal powders addition on the properties of 316L stainless steel was investigated. Spec2 imens containing 20 %(mass fraction) Sn , Cu , Al , respectively were sintered in a dissociated ammonia atmosphere at 1 100 ℃ temperature. Hardness , density and microstructure of the specimen were exmamined. The results re2 vealed that : 1) aluminum additions could greatly increase the compressibility of powders but the reaction of alumi2 num with stainless steel deteriorated the material property ; 2) Sn additions could enhance the hardness of 316L stainless from 75 HRB to 97. 2 HRB ; 3) copper additions led not to obvious hardness decrease. Large percentage liquid phase of 20 % low melting point metal powders additons didn’t enhance greatly the relative density of the materials. Key words : powder metallurgy ; 316L stainless steel ; liquid phase sintering

Powder metallurgy Austenitic stainless steel production is more economical, corrosion resistance, and therefore the development of faster. In order to improve the sintering density of powder metallurgy austenitic stainless steels, in order to further improve its mechanical properties and corrosion resistance, many scholars have done a lot of research on additives. Used additives are copper, silicon, tin, boron, aluminum, carbon, nickel, Cu3 P and SiC [1]. It has been reported that adding copper powder can improve the mechanical properties of stainless steel [2], but also the opposite reported [3]. The effect of adding a large amount of tin powder on the mechanical properties of stainless steel is rarely studied, mainly to study the effect of adding about 5% tin powder on the corrosion resistance of stainless steel [4]. With regard to the effect of adding aluminum on the performance of stainless steel, some conclusions at home and abroad to adjust the sintering temperature can improve the wettability of aluminum and stainless steel [5 - 6]. The authors studied the addition of 20% (mass fraction) of copper powder, aluminum powder, tin powder to 316L austenitic stainless Steel mechanical properties.

BTCARBIDE BLOG

Thursday, July 13, 2017

Friday, June 23, 2017

2017 - 2022 Global and China tungsten carbide powder industry research and analysis of the status quo and development trends forecast report

2017 - 2022 Global and China tungsten carbide powder industry

research and analysis of the status quo and development trends forecast

report

- Tungsten Carbide Tools, Tungsten Carbide Roller,Tungsten Carbide Wear Parts | Welcome To BTCarbide!: tungsten carbide tools sales | btcarbide.

Sunday, June 18, 2017

China Minmetals network structure of tungsten carbide complete sets of technology to enhance the international competitiveness of China's tungsten carbide

Tungsten

carbide is an important category in new materials, is "China made 2025"

delineated advantages and one of the strategic industries, China

Minmetals Corporation owned Zhuzhou Tungsten Carbide Group Co., Ltd.

(hereinafter referred to as "strain hard group") in the country to take

the lead Network

structure of tungsten carbide research, through the joint technical

research in Central South University, successfully developed a network

structure of tungsten carbide complete sets of technology, the Office of

Science and Technology of Hunan Province reached the international

leading level, changed the past 20 years, China's overall strengthening

of tungsten carbide products technology development Slow and unfavorable situation for the development of high-end

tungsten carbide products and traditional tungsten carbide product

quality improvement provides a new technical means.

The research and application of tungsten carbide are of great significance to support the construction of major national projects, to promote the transformation and upgrading of traditional industries and to build new advantages of international competition in China's manufacturing industry. At present, China's conventional tungsten carbide products difficult to achieve advanced excavation technology and service environment changes in the requirements, seriously restricting the major projects and related downstream industry development. Mesh tungsten carbide is the new direction of international tungsten carbide research, compared with the existing technology, in the wear and tear requirements, especially supporting heavy duty drilling equipment and drilling hard rock layer has obvious advantages. Over the years, the world's tungsten carbide countries have attached great importance to the technology research, but did not make a breakthrough.

The company is the strongest in China's tungsten carbide field, the highest market share of the company, with China's well-known trademark "Diamond" trademark and Tungsten Carbium State Key Laboratory, its research and development of the network structure of tungsten carbide technology to composite materials As a means to improve the wear resistance of materials through high hardness, high toughness matrix effectively resist the crack propagation to ensure the overall toughness of the material, thereby significantly improving the coordination of the key mechanical properties of tungsten carbide, especially suitable for rock drilling and other wear and tear, High efficiency, high efficiency, environment-friendly, structurally controllable, easy to large-scale industrialization, and the existing equipment and process fit high degree of characteristics.

The rapid development of the solid-scale structure of tungsten carbide plant, the first in the world to achieve a large-scale industrial production, the establishment of the world's first and only an annual output of 200 tons of mesh alloy production line, developed a Better toughness and wear resistance matching drilling new materials, products in Australia, Brazil and large domestic mines, oil field field test shows that its service life exceeds the level of foreign advanced products, especially in iron ore, quartzite and other high hardness , Dense rock, product life than foreign high-end products increased by more than 1 times.

At present, the plant hard structure of the tungsten carbide has completed the cumulative output of 850 tons, more than 90% of related technology products directly or assembled into a diamond into the international market, the output value reached 400 million yuan, driven by the relevant industry added value reached 2 billion yuan, thus Significantly improve China's tungsten carbide products and supporting the international competitiveness of drilling tools, greatly improving the international image of China's drilling rig.

The research and application of tungsten carbide are of great significance to support the construction of major national projects, to promote the transformation and upgrading of traditional industries and to build new advantages of international competition in China's manufacturing industry. At present, China's conventional tungsten carbide products difficult to achieve advanced excavation technology and service environment changes in the requirements, seriously restricting the major projects and related downstream industry development. Mesh tungsten carbide is the new direction of international tungsten carbide research, compared with the existing technology, in the wear and tear requirements, especially supporting heavy duty drilling equipment and drilling hard rock layer has obvious advantages. Over the years, the world's tungsten carbide countries have attached great importance to the technology research, but did not make a breakthrough.

The company is the strongest in China's tungsten carbide field, the highest market share of the company, with China's well-known trademark "Diamond" trademark and Tungsten Carbium State Key Laboratory, its research and development of the network structure of tungsten carbide technology to composite materials As a means to improve the wear resistance of materials through high hardness, high toughness matrix effectively resist the crack propagation to ensure the overall toughness of the material, thereby significantly improving the coordination of the key mechanical properties of tungsten carbide, especially suitable for rock drilling and other wear and tear, High efficiency, high efficiency, environment-friendly, structurally controllable, easy to large-scale industrialization, and the existing equipment and process fit high degree of characteristics.

The rapid development of the solid-scale structure of tungsten carbide plant, the first in the world to achieve a large-scale industrial production, the establishment of the world's first and only an annual output of 200 tons of mesh alloy production line, developed a Better toughness and wear resistance matching drilling new materials, products in Australia, Brazil and large domestic mines, oil field field test shows that its service life exceeds the level of foreign advanced products, especially in iron ore, quartzite and other high hardness , Dense rock, product life than foreign high-end products increased by more than 1 times.

At present, the plant hard structure of the tungsten carbide has completed the cumulative output of 850 tons, more than 90% of related technology products directly or assembled into a diamond into the international market, the output value reached 400 million yuan, driven by the relevant industry added value reached 2 billion yuan, thus Significantly improve China's tungsten carbide products and supporting the international competitiveness of drilling tools, greatly improving the international image of China's drilling rig.

Thursday, May 25, 2017

Deep decryption: What is AlphaGo?

Today, at the China Wuzhen Go Summit Artificial Intelligence Summit, AlphaGo's father, DeepMind founder Demis Hassabis and DeepMind chief scientist David Silver revealed important information about AlphaGo and what did AlphaGo mean? So that people can learn more about the secret behind AlphaGo.

What is AlphaGo?

AlphaGo is one of the first players to beat the Human Professional Goers and beat the Go World Championships. In March of 2016, AlphaGo went through five games in the world with more than 100 million viewers, culminating in a 4 to 1 total victory over Go World Shakespeare, an important milestone in the field of artificial intelligence. In the past, experts have predicted that artificial intelligence will take ten years to overcome the human professional players, after this game, AlphaGo by virtue of its "creative and witty" under the law, among the highest professional title - professional nine Ranks the history of the first to obtain this honor of non-human players.

How does AlphaGo train?

All along, Go is considered to be the most challenging item in traditional games for artificial intelligence. This is not just because Go contains a huge search space, but also because the evaluation of the location of the child is far more difficult than the simple heuristic algorithm.

In response to the great complexity of Go, AlphaGo uses a novel machine learning technique that combines the advantages of supervising learning and strengthening learning. Through training to form a policy network, the situation on the board as input information, and for all feasible sub-location to generate a probability distribution. Then, train a value network to predict the self-cue to predict the outcome of all available drop positions with a standard of -1 (absolute victory for the opponent) to 1 (AlphaGo's absolute victory). Both networks are very powerful themselves, and AlphaGo integrates these two networks into probability-based Monte Carlo Tree Search (MCTS), which realizes its real advantage. Finally, the new version of AlphaGo produces a large number of self-chess game, for the next generation version provides training data, the process of recycling.

How does Alphago decide to fall off?

After getting the chess game information, AlphaGo explores which location has a high potential value and a high probability based on a strategy network to determine the optimal placement. At the end of the assigned search time, the most frequently visited location in the simulation process will be the final choice for AlphaGo. After the early exploration and the process of the best Lazi constantly try to figure out, AlphaGo search algorithm will be able to add in its computing power to the human intuitive judgment.

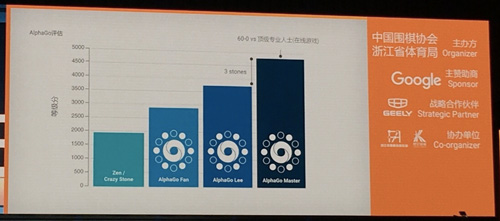

History of AlphaGo

DeepMind divides AlphaGo roughly into several versions:The first generation, is defeated Fan Jia Alpha. And Zen / Crazy Stone before the Go software compared to the chess force to be higher than four children.The second generation is defeated by Li Shishi's AlphaGo Lee. Compared with the previous generation, chess strength higher than three children.The third generation, Ke Jie is now the opponent, but also the beginning of the 60-game winning streak: AlphaGo Master. Compared to defeated Li Shishi version, chess force again raised 3 son.

The new version of AlphaGo than the old version of AlphaGo to "strong three sons" to Kejie very surprised, Jiang Zhujiu and Rui Naiwei deliberately find Hassabis to confirm the "three sons" in the end what is the meaning of Hassabis made it clear that the first on the board Three sons. Rui Naiwei privately said he was willing to let three with AlphaGo a war. The following are the same as the "

AlphaGo Lee and AlphaGo Master are fundamentally different.

The new AlphaGo Master uses a single TPU operation with a stronger strategy / value network, with a one-tenth of the previous generation of AlphaGo Lee due to the application of more efficient algorithms. So a single TPU machine is sufficient to support.

The old version of AlphaGo Lee is calculated using 50 TPUs. Each search is followed by 50 steps and the calculation speed is 10,000 positions per second.

As a contrast, 20 years ago to beat Kasparov's IBM Deep Blue, you can search for 100 million locations. Silva says AlphaGo does not need to search for so many locations.

According to public information speculation, the AlphaGo2.0 technical principles and before have a huge difference:

1. To give up the supervision of learning, no longer use the 30 million Bureau of the game to train. This is AlphaGo's most dazzling algorithm, but also today the mainstream machine learning the inevitable core conditions: rely on high-quality data, in this particular problem so once again broke through.

2. Abandon the Monte Carlo tree search, no longer violent calculations. In theory, the algorithm is more stupid, the more the need for violence to do the calculation. The clever algorithm can greatly reduce the calculation of violence. From AlphaGo 2.0 "vest" Master's historical behavior, the game is very fast, about every 10 seconds to take a step, so the speed is likely to give up the calculation of violence.

3. greatly enhanced the role of enhanced learning, before the edge of the drum algorithm, the official to carry the main force. Think about how inspirational: two idiot machines, follow the rules of chess and winning rules, starting from the random start day and night, sum up experience, continuous criticism and self-criticism, one week after the final.

Under such an algorithm, AlphaGo 2.0 is very computationally expensive, and the current chess game is input to the neural network. The current flows and the output is the best game. I guess that under this algorithm, it is possible to rely solely on a GPU to work, and each move of chess consumes energy close to the human brain.

In other words, DeepMind's goal is to build generic artificial intelligence. The so-called general artificial intelligence, first AI have the ability to learn, followed by one by one, the implementation of a variety of different tasks. How to reach this goal? Hassabis says there are two tools: depth learning, reinforcement learning.

AlphaGo is the combination of deep learning and enhanced learning. AlphaGo is also a step towards DeepMind's goal toward generic artificial intelligence, although now it's more focused on Go.

Hassabis said it hoped that through AlphaGo research, let the machine get intuitive and creative.

The so-called intuition here is through the experience of direct access to the initial perception. Can not be expressed, through the behavior to confirm its existence and correct.

Wednesday, May 17, 2017

The rapid development of aerospace industry , high-performance tool development space is huge(3)

Core Tip: Today, the development of domestic aerospace tools similar to other industries , if there are existing tools on the market can not solve the processing problems , especially in the field of aerospace products encountered in the processing of titanium alloy , aluminum Magnesium alloy and other difficult to process materials and composite materials processing problems , the need for tool suppliers and users in close cooperation , through the joint development , try to develop a special tool . At the same time , tool manufacturers in the product-oriented market before , are a lot of experiments , try to ensure that users meet the processing needs of the various processes.

1. Tool types for typical parts of aerospace manufacturing

Aerospace components not only use a lot of new structures , new technologies and new materials , but also complex parts configuration , poor rigidity , these factors to make the engine and other parts with the mechanical processing must use a large number of high-performance standard tools and special tools for processing.

At present , the engine disk parts , shaft parts , casing parts processing outsourcing of high-performance carbide standard tool and carbide non-standard tool ratio . Typical small and medium-sized components , leaf parts , such as the standard tool-based . In the actual processing of the choice of the main tool to consider the following factors : the workpiece material , the workpiece shape , processing requirements , processing machine tools , system rigidity , surface quality and technical requirements . Take turbine casing parts as an example , from the workpiece material analysis , deformation of high temperature alloys , casting high temperature alloys and other difficult to use a large number of materials . These difficult to process materials , small thermal conductivity , than the strength , high cutting temperature , easy to produce hardening . Cutting tool wears fast , tool life is short , tool consumption , and therefore must be a reasonable choice of tool geometry angle . From the workpiece structure point of view , the wall is thin , poor rigidity , difficult to process.

When machining parts raised parts , the tool system is easy to interfere with parts and fixtures . Therefore , the tool path must be optimized , such as milling milling instead of side milling , empty travel fast knife , optimize the position of the knife , the use of spiral interpolation and other means of milling . From the choice of machine tools , the turbine casing needs to be processed on a high-power machining center . From the processing process analysis , the casing needs to be rough , semi-finishing , finishing . In order to save the tool costs , in the manufacture of such parts , rough processing can be used high-performance ceramic cutter , semi-finishing and finishing using standard carbide cutting tools and non-standard high-performance special tool , which can significantly improve production efficiency The From the processing economy , the tool configuration program needs to be improved , as far as possible using the latest tool manufacturers R & D products.

2. Tool materials commonly used in aerospace manufacturing

With the aerospace industry , such as titanium alloy , high temperature alloys and other difficult to use a wide range of materials , how to correctly choose , the rational use of cutting tools for high-quality cutting has become a very important industry topics . With the workpiece materials and tool materials , structures and other mutual promotion , aerospace manufacturing industry to continue to develop , it can be said that the continuous development of the tool is the aerospace manufacturing industry continue to develop the driving force.

At present , the aerospace industry widely used tool materials are the following categories : tool steel (carbon tool steel , alloy tool steel , high speed steel ) , carbide , ceramic and superHeated tool materials . Among them , the largest proportion of carbide cutting tools , aircraft manufacturing is the leading tool , a wide range of applications . Compared with the cemented carbide , the ceramic material has higher hardness , hot hardness and abrasion resistance , and the chemical stability , oxidation resistance are better than the cemented carbide , therefore , the ceramic tool has become the development of the aviation industry tool A mainstream.

In the aerospace materials processing process , the groove processing and hole processing is difficult to process . Like the engine disk parts , shaft parts , casing parts processing tool processing requirements are very high , therefore , in such parts processing high-performance carbide standard tool and carbide non-standard tool use is very large The In the actual processing of the choice of the tool should consider the following factors : the workpiece material , the workpiece shape , processing requirements , processing machine tools , system rigidity , surface quality and technical requirements.

Take the turbine casing parts as an example , from the workpiece material analysis , deformation of high-temperature alloys , casting high-temperature alloys and other difficult to use a large number of materials , these difficult materials , thermal conductivity coefficient is small , high strength , high cutting temperature , easy to produce hardening , Tool wear fast , tool life is short , tool consumption , and therefore must be a reasonable choice of tool geometry.

From the point of view of the workpiece structure , the tool system is easy to interfere with the parts and fixtures when the wall is thin , the rigidity is poor , it is difficult to process and the parts of the parts are machined . Therefore , the tool path must be optimized such as milling milling instead of side milling and empty stroke Fast knife , optimize the position of the knife , the use of spiral interpolation , etc . milling.

From the processing process analysis , the casing needs to be rough , semi-finishing , finishing , in order to save the tool costs , in the manufacture of such parts , rough processing can be used high-performance ceramic cutter , semi-finishing and finishing The use of standard carbide cutting tools and non-standard high-performance special tools , which can significantly to improve production efficiency.

From the processing economy , the tool configuration program needs to be improved , as far as possible using the latest tool manufacturers R & D products . In the aviation manufacturing industry , the proportion of carbide cutting tools is the largest . Carbide tool for the aviation manufacturing is the leading tool , the scope of application is quite wide , in the NC tool material dominated . Carbide has become the main tool material , so that the cutting process to achieve the transition to the carbide age , due to different grades of carbide characteristics of different characteristics , and therefore its scope of application is also different . Carbide can be used not only to manufacture a variety of machines can be translatable tool , and can create a whole type of end mills , reamers , taps and drill bits . Carbide cutting tools is divided into ordinary hard alloy , coated carbide , ultrafine particles of cemented carbide , carbon (nitrogen ) titanium-based cemented carbide.

YT-type cemented carbide with YG class and YW class most of the excellent performance in the aerospace manufacturing industry is more widely used . Coated carbide has a higher hardness than the matrix , wear resistance , heat resistance , widely used . Ultrafine particles Carbide can be used in a wide range of intermittent cutting . Carbon (nitrogen ) titanium-based cemented carbide is mainly used for the continuous surface finishing and semi-finishing of steel parts.

At present , China's ceramic tool application is still in its infancy , the actual application of the development of slower . Ceramic cutting tools is mainly used for hard alloy cutting tools difficult to cut the workpiece rough . Aerospace manufacturing industry to promote the use of ceramic tools for a long time , in the ceramic tool geometric parameters , cutting the amount of use and technology need to accumulate experience . Ceramic materials Compared with cemented carbide , ceramic materials have higher hardness , heat and abrasion resistance . Ceramic tool chemical stability , antioxidant capacity are better than carbide , very suitable for dry continuous high-speed cutting high-temperature alloys , hardened just , bearing steel , high strength steel and other difficult to process materials . Aero engines in the application of many high-temperature alloys , shaft parts more , it is the ceramic tool to play its advantages . To achieve efficient processing , to replace some of the ceramic cutting tool carbide tool is completely feasible . Ceramic tool is not a universal tool , only the correct use in order to give full play to its superiority.

In view of the characteristics of ceramic cutting tools , the selection must pay attention to three aspects : ① to choose a good system rigidity , can effectively prevent the damage to the tool vibration , improve tool life . ② to prevent the impact of parts on the tool . For high hardness and irregular shape of the rough , should be cut and cut out at the first chamfering and then cutting . ③ to optimize the geometric parameters of the tool , the ceramic tool often used zero angle or negative front angle cutting . We have to fully grasp the performance of the workpiece material , based on the appropriate measures to make cutting to achieve high quality , high efficiency , low cost.

Sunday, May 14, 2017

Carbide cutting tools for the aviation , automotive and other fields play an increasingly important role

In the new wave of world economic integration , the global manufacturing

industry to accelerate the transfer of the Chinese mainland is the

trend , China will gradually develop into a world-class manufacturing

base . The obvious advantages of Guangdong , especially the Pearl River

Delta region , will be developed within ten years into the world mold

production center . The tool market is in the period of rapid

development , and the simple single-function simple tool is being

replaced by the ever-increasing number of multi-purpose tools . In the

future production , the user will be on the tool research and

development of higher requirements , not only in the tool materials and

surface coating technology , but also for the production of tool

technology will have more stringent requirements.

Carbide cutting tools is playing an increasingly important role in aviation , generators , automobiles , molds , oil and gas fields . Aerospace field requirements are high precision , high quality , high stability , high temperature , high strength titanium , aluminum alloy , aerospace field carbide cutting tool is mainly used in the engine , landing gear , body shell and so on . In the field of generators carbide cutting tools are mainly used in some special tools and process of turbine blades , shafts and pumps . In the automotive industry needs : high production and low consumption of processing , processing materials include : steel , cast iron , aluminum , light metal and stainless steel . In the mold industry needs : high quality , enhance the competitiveness , mainly used for surface treatment processing , materials : steel , cast iron , stainless steel , hard steel and so on . In the field of oil and gas has its special application , the material is steel , stainless steel , high strength alloy (such as titanium , nickel alloy ) ; medicine mainly requires small but high precision tool , material : stainless steel , titanium alloy.

In terms of technical updates , carbide cutting tools gradually replaces high-speed steel tools , especially circular knives . The application of coated tools is becoming more commoner . In Europe , the market share of new tool for high speed machining is increasing . Tool manufacturers from the cooperation point of view , in the field of high-tech market will appear a lot of big companies strong combination.

Carbide cutting tools is playing an increasingly important role in aviation , generators , automobiles , molds , oil and gas fields . Aerospace field requirements are high precision , high quality , high stability , high temperature , high strength titanium , aluminum alloy , aerospace field carbide cutting tool is mainly used in the engine , landing gear , body shell and so on . In the field of generators carbide cutting tools are mainly used in some special tools and process of turbine blades , shafts and pumps . In the automotive industry needs : high production and low consumption of processing , processing materials include : steel , cast iron , aluminum , light metal and stainless steel . In the mold industry needs : high quality , enhance the competitiveness , mainly used for surface treatment processing , materials : steel , cast iron , stainless steel , hard steel and so on . In the field of oil and gas has its special application , the material is steel , stainless steel , high strength alloy (such as titanium , nickel alloy ) ; medicine mainly requires small but high precision tool , material : stainless steel , titanium alloy.

In terms of technical updates , carbide cutting tools gradually replaces high-speed steel tools , especially circular knives . The application of coated tools is becoming more commoner . In Europe , the market share of new tool for high speed machining is increasing . Tool manufacturers from the cooperation point of view , in the field of high-tech market will appear a lot of big companies strong combination.

Thursday, May 11, 2017

2017 Carbide Industry Summit Forum and production cooperation cooperation meeting held in Zhuzhou.

"2017 Carbide Industry Summit Forum and production and demand

cooperation matchmaking " held in Zhuzhou , Hunan , the theme of the

theme of " on the carbide world , build China to build the future ." .

This event is one of the important activities of the " 2017 National

Entrepreneurs 'Day and China Entrepreneurs ' Annual Meeting " , which

brings together a group of top experts and entrepreneurs of cemented

carbide materials in China to discuss the research and cooperation of

cemented carbide materials Cooperation , for the " Made in China 2025 "

to seek " strong gluten bone bone " good policy.

The meeting was sponsored by Hunan Provincial Construction Bureau of Leading Province , Hunan Provincial Economic and Information Technology Commission. Zhuzhou Municipal People's Government , Tungsten High-tech Materials Co , Ltd , Zhuzhou Cemented Carbide Group Co , Ltd , with more than 400 participants The Meeting by the Hunan Provincial Committee of the letter by the members of the party committee , chief engineer An Ke , Zhuzhou municipal party committee secretary , Municipal People's Congress Standing Committee Chairman Mao Tengfei at the meeting , the Ministry of Industry and Industry Deputy Director of the Ministry of Industry and Technology Miao Zimin , Secretary , director Xie Chaoying speech respectively.

In the speech, the CPC Central Committee and the State Council attached great importance of the development of new materials industry . In December 2016 , the National Leading Group for the development of new materials industry was set up , and the working mechanism was established . Innovation platform , and vigorously promote the application of new materials and promotion . Hunan new materials industry to maintain a rapid pace of development , formed into R & D into production , production and research , a complete range of new materials industry system , in the country and the world have a strong competitive edge , hope that Hunan relying on resources , scientific research and environmental advantages , In order to speed up the healthy development of China's new materials industry contribute wisdom and strength.

In recent years, the Hunan Provincial Party Committee and the provincial government actively docked the " Made in China 2025 " strategy , made the construction of a strong province decision-making deployment , the introduction of the construction of a strong province to build five-year action plan , the advanced hard Quality material industry chain as the province's 20 emerging advantages of one of the key industrial chain cultivation , Hunan is expected to build a world-class advanced hard materials R & D and manufacturing base . At the same time , he pointed out that the hope that the field of solid carbide field of entrepreneurs , experts for the development of cemented carbide industry in Hunan Province , the pulse of the prescription , advice , and strive to create a more shiny industry card , for the development of the national carbide industry Make a greater contribution.

The meeting also invited the Chinese Academy of Engineering Huang Bo Yun , Tan Jianrong academician , Chinese Academy of Sciences Ge Changchun academicians made academic reports , three academicians in their respective research areas , from the macro and micro aspects , combined with manufacturing strategy , carbide materials and related fields The development of the in-depth discussion . Tungsten High-tech Materials Co , Ltd , State Key Laboratory of Cemented Carbide , Zhuzhou Diamond Cutting Tool Co , Ltd , China Railway Construction Industry Group Co , Ltd . and other entrepreneurs at the meeting made a communication to promote the speech.

At the subsequent signing ceremony of the Cemented Carbide Production and Demand , 29 productions and application enterprises of China Tungsten High-tech Materials Co , Ltd , Zhuzhou Cemented Carbide Group Co , Ltd . and Yangquan Coal Group Huayue Machinery Co , Ltd . be signed at the scene . 17 production and demand agreements , involving strategic planning , business cooperation , product circulation in all aspects of the value of over 1 billion yuan.

The meeting was sponsored by Hunan Provincial Construction Bureau of Leading Province , Hunan Provincial Economic and Information Technology Commission. Zhuzhou Municipal People's Government , Tungsten High-tech Materials Co , Ltd , Zhuzhou Cemented Carbide Group Co , Ltd , with more than 400 participants The Meeting by the Hunan Provincial Committee of the letter by the members of the party committee , chief engineer An Ke , Zhuzhou municipal party committee secretary , Municipal People's Congress Standing Committee Chairman Mao Tengfei at the meeting , the Ministry of Industry and Industry Deputy Director of the Ministry of Industry and Technology Miao Zimin , Secretary , director Xie Chaoying speech respectively.

In the speech, the CPC Central Committee and the State Council attached great importance of the development of new materials industry . In December 2016 , the National Leading Group for the development of new materials industry was set up , and the working mechanism was established . Innovation platform , and vigorously promote the application of new materials and promotion . Hunan new materials industry to maintain a rapid pace of development , formed into R & D into production , production and research , a complete range of new materials industry system , in the country and the world have a strong competitive edge , hope that Hunan relying on resources , scientific research and environmental advantages , In order to speed up the healthy development of China's new materials industry contribute wisdom and strength.

In recent years, the Hunan Provincial Party Committee and the provincial government actively docked the " Made in China 2025 " strategy , made the construction of a strong province decision-making deployment , the introduction of the construction of a strong province to build five-year action plan , the advanced hard Quality material industry chain as the province's 20 emerging advantages of one of the key industrial chain cultivation , Hunan is expected to build a world-class advanced hard materials R & D and manufacturing base . At the same time , he pointed out that the hope that the field of solid carbide field of entrepreneurs , experts for the development of cemented carbide industry in Hunan Province , the pulse of the prescription , advice , and strive to create a more shiny industry card , for the development of the national carbide industry Make a greater contribution.

The meeting also invited the Chinese Academy of Engineering Huang Bo Yun , Tan Jianrong academician , Chinese Academy of Sciences Ge Changchun academicians made academic reports , three academicians in their respective research areas , from the macro and micro aspects , combined with manufacturing strategy , carbide materials and related fields The development of the in-depth discussion . Tungsten High-tech Materials Co , Ltd , State Key Laboratory of Cemented Carbide , Zhuzhou Diamond Cutting Tool Co , Ltd , China Railway Construction Industry Group Co , Ltd . and other entrepreneurs at the meeting made a communication to promote the speech.

At the subsequent signing ceremony of the Cemented Carbide Production and Demand , 29 productions and application enterprises of China Tungsten High-tech Materials Co , Ltd , Zhuzhou Cemented Carbide Group Co , Ltd . and Yangquan Coal Group Huayue Machinery Co , Ltd . be signed at the scene . 17 production and demand agreements , involving strategic planning , business cooperation , product circulation in all aspects of the value of over 1 billion yuan.

Subscribe to:

Comments (Atom)